Read through the following instructions before installing the dryer, and keep this manual for future reference.

WARNING Certain internal parts are intentionally not grounded and may present a risk of electric shock only during servicing. Service Personnel - Do not contact the following parts while the appliance is energized: Control board and inlet valve.

WARNING Remove the door from all discarded appliances to prevent a child from suffocating.

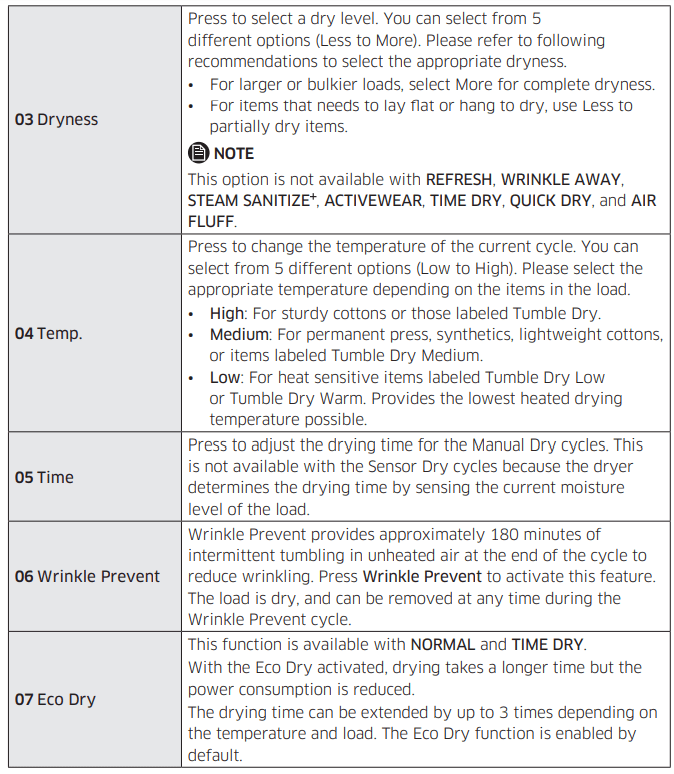

WARNING

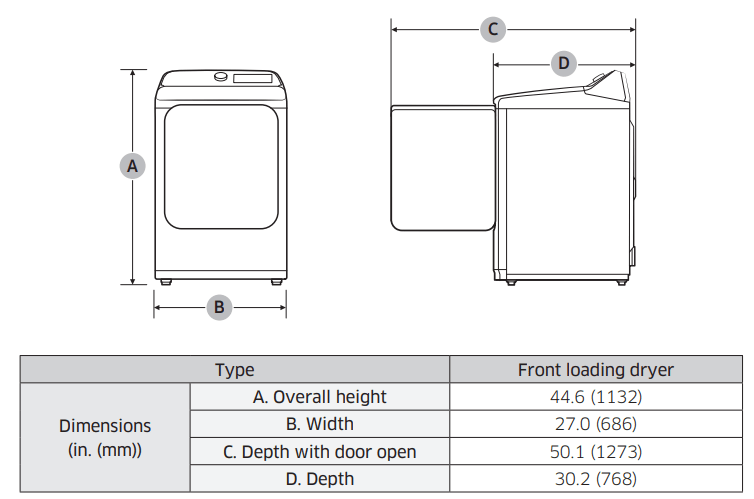

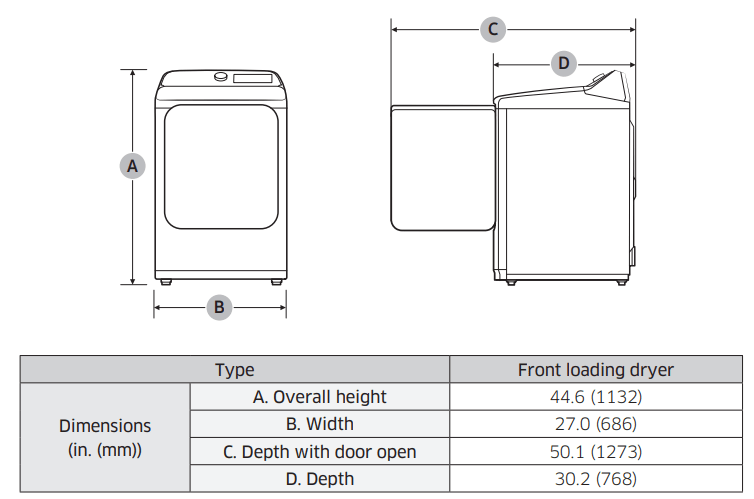

Dimensions

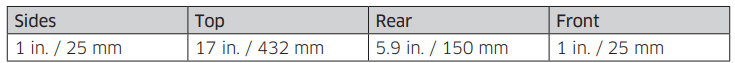

Clearance requirement

This clearance requirement is applicable for dryers only.

NOTE

WARNING

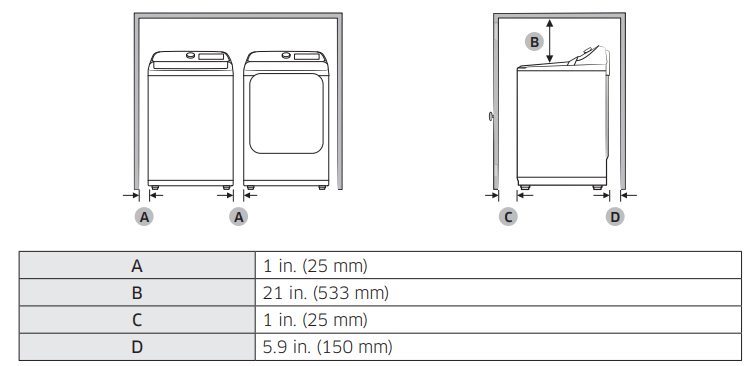

Minimum clearance for stable operation:

If both the washer and a dryer are installed in the same location, the front of the alcove or closet must have two unobstructed air openings for a combined minimum total area of 72 in.² (465 cm²).

This clearance requirement is applicable for washer and dryer pair installation.

Side by side installation

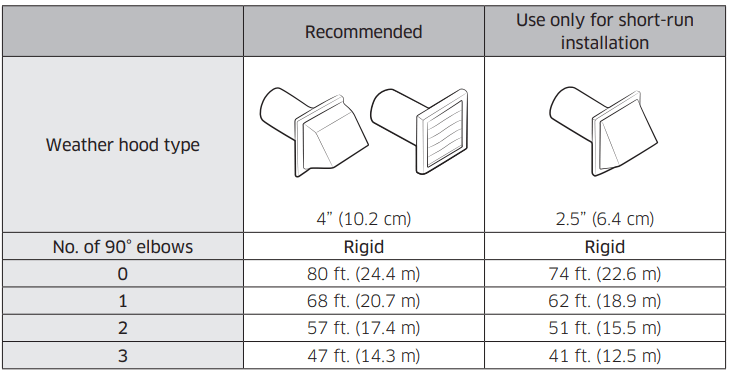

NOTE * Use a 4-inch (10.2 cm) diameter rigid aluminum or galvanized steel duct.

If you integrate the dryer’s vent system with an existing exhaust system, make sure:

Manometer measurements

The static pressure in any exhaust system must not exceed 0.83 inches of water column or be less than 0. Note that these values are measured with the dryer running with a manometer presented to the exhaust duct that connects to the dryer. The dryer tumbler must be empty and lint filter clean.

Exhausting requirements

The dryer must not be exhausted into a chimney, a wall, a ceiling, an attic, a crawl space, or a concealed space of a building. Exhausting the dryer to the outside will prevent large amounts of lint and moisture from being blown into the room.

In the United States and Canada

WARNING

Gas requirements

• Use only natural or LP (liquid propane) gases.

• The installation must be conformed with local codes, or in the absence of local codes, with the national fuel gas code, ANSI Z223.1/NFPA 54, latest revision (for the UNITED STATES), or with the natural gas and propane installation code, CSA B149.1 (for Canada).

• Gas dryers are equipped with a burner vent for use with natural gas. If you plan to use your dryer with LP (liquid propane) gas, it must be converted for safe and proper performance by a qualified service technician. (LNG models only) You must check the burner of your model and use the proper LP Kit accordingly. To check the detail information of the burner, open the door and check the rating label location on the door frame.

- 20,000 BTU: LPKIT-4/XAA (DC98- 04114A)

- 22,000 BTU: LPKIT-3/XAA (DC99- 00792A)

NOTE

Commonwealth of Massachusetts installation instructions

Your dryer must be installed by a licensed plumber or gas fitter. A “T” handle manual gas valve must be installed in the gas supply line to your dryer. If a flexible gas connector is used to install your dryer, the connector can be no longer than 3’ (36”).

WARNING

WARNING

Gas models

WARNING

Electric models

WARNING

Electrical connections

Before operating or testing, follow all grounding instructions in the “Grounding” section. An individual branch (or separate) circuit serving only your dryer is recommended.

Do not use an extension cord.

Gas models – U.S. and Canada

A 120 volt, 60 Hz AC approved electrical service with a 15-ampere fuse or circuit breaker is required.

Electric models – U.S. only

Most U.S. dryers require a 120 / 240 volt, 60 Hz AC approved electrical service. Some require 120 / 208 volt, 60 Hz approved electrical service. The electric service requirements can be found on the data label located behind the door. A 30-ampere fuse or circuit breaker on both sides of the line is required.

WARNING

Risk of Electric Shock

When local codes allow, you can connect the dryer’s electrical supply with a new power supply cord kit, marked for use with a dryer, that is U.L. listed and rated at a minimum of 120 / 240 volts, 30-amperes with three No. 10 copper wire conductors terminated with closed loop terminals, open-end spade lugs with turned up ends, or with tinned leads.

Electric models – Canada Only

NOTE

In Canada, you may not convert a dryer to 208 volts.

This dryer must be installed by a qualified technician. The installer is responsible for connecting the dryer to the main power while observing the relevant safety regulations of your area.

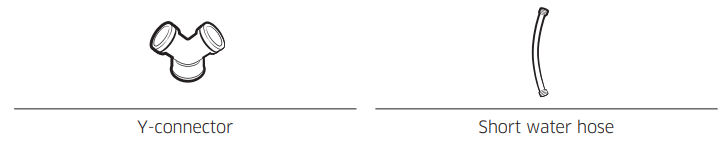

Make sure all the parts are included in the product package. If you have a problem with the dryer or the parts, contact a local Samsung customer center or the retailer.

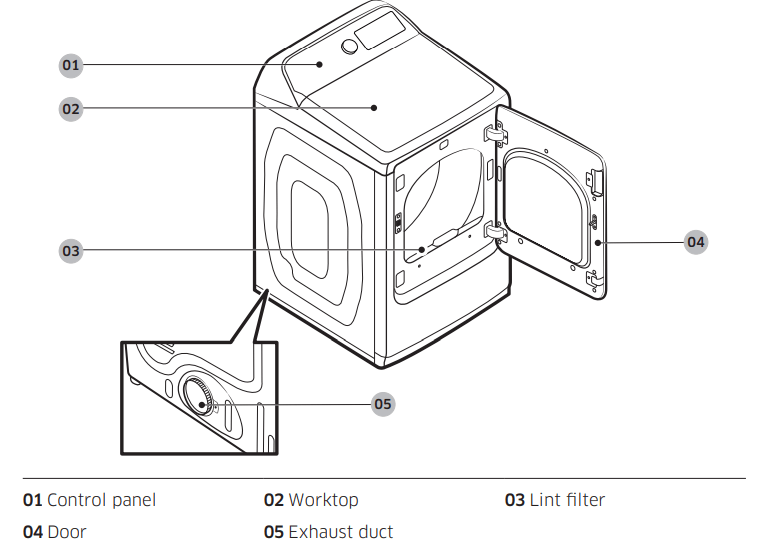

Parts supplied

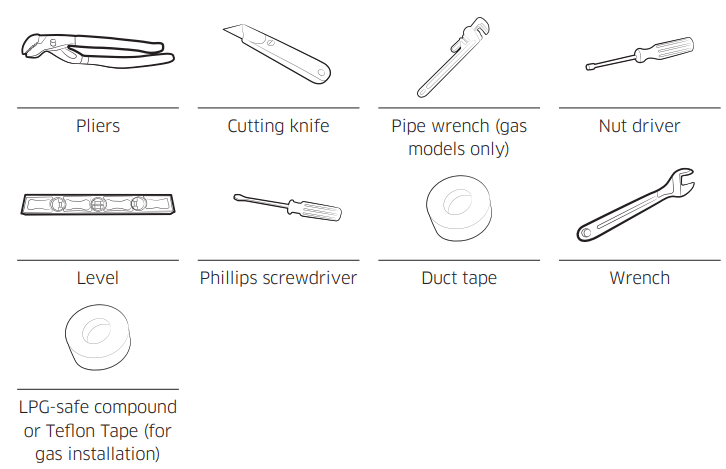

Tools needed for installation

|

WARNING Packing materials can be dangerous to children. Keep all packing materials (plastic bags, polystyrene, etc.) out of children’s reach.

Make sure you have a qualified technician install the dryer. Step by step installation instructions start below.

CAUTION

Before installing your dryer, remove the packing in the duct.

NOTE

Before connecting the gas line, make sure you have read the “Gas requirements” section on page 16.

Before connecting the electrical wiring, make sure you have read the “Electrical requirements” section on page 17.

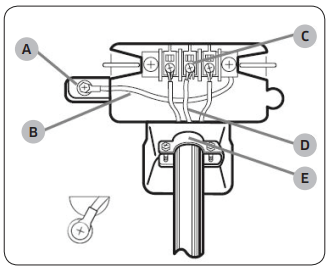

3-wire system

A. External ground connector

B. Neutral grounding wire (white)

C. Center silver-colored terminal block screw

D. Neutral wire (white or center wire)

E. 3/4” (1.9 cm) UL-listed strain relief

CAUTION

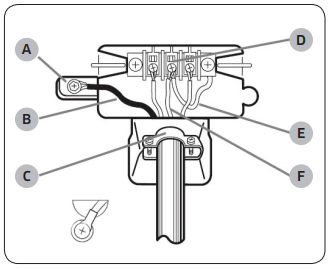

4-wire system

A. External ground connector

B. Green or bare copper wire of power cord

C. 3/4” (1.9 cm) UL-listed strain relief

D. Center silver-colored terminal block screw

E. Neutral grounding wire (white)

F. Neutral wire (white or center wire)

1. Remove the external ground connector’s screw and connect the ground wire (green or unwrapped) of the power cable to the screw.

CAUTION

- To connect the ground wire to the neutral position without through contact A (cabinet ground), contact a technician. This is not user serviceable.

- Ring-type terminals are recommended. If using strap terminals, make sure they are tightened.

2. Loosen or remove the screws from the center terminal block.

3. Connect the neutral wire (white or center wire) and ground wire (white) to the center screw of the terminal block. Tighten the screw.

4. Connect the other wires to the outer terminal block screws. Tighten the screws.

5. Tighten the strain relief screws.

6. Insert the tab of the terminal block cover into the rear slot of the dryer. Secure the cover with a hold-down screw.

WARNING

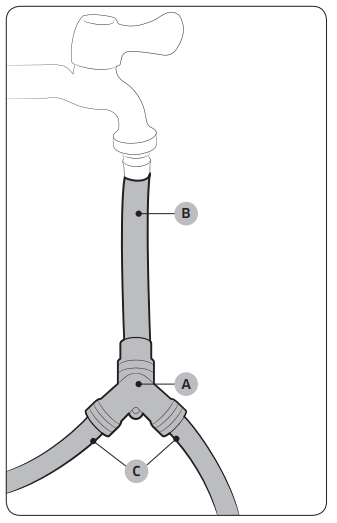

The dryer must be connected to a cold water tap using the provided water hoses.

1. Close the cold water tap. If you have a washer’s cold water hose attached to the cold water tap, unscrew and remove the hose. Then, connect the female end of the Y-connector to the cold water tap.

2. Connect the straight end of the water hose to the Y-connector.

3. Using pliers, tighten the coupling an additional two-thirds turn. Do not overtighten because the coupling may be damaged.

4. Connect the angled end of the water hose to the filling valve at the bottom of the rear frame. Turn the coupling manually until it is tight.

5. Using pliers, tighten the coupling an additional two-thirds turn. Do not overtighten because the coupling may be damaged.

6. If you detached the cold water hose from your washer, attach the hose to the open end of the Y-connector, tighten the coupling by hand until it is tight, and then, using a pliers, tighten an additional two-thirds turn.

7. Open the cold water tap, and then check for any leaks.

If the Y-connector cannot be directly connected to the cold water tap, use the short hose. See the “Using the short hose as an extension” section on page 26.

Using the short hose as an extension

1. Close the cold water tap. If you have a washer’s cold water hose attached to the cold water tap, unscrew and remove the hose. Then, connect the short hose (B) to the cold water tap. Turn the coupling by hand until it is tight.

2. Using pliers, tighten the coupling an additional two-thirds turn. Do not overtighten because the coupling may be damaged.

3. Connect the Y-connector (A) to the brass male end of the short hose. Turn the coupling by hand until it is tight.

4. Using pliers, tighten the coupling an additional two-thirds turn. Do not overtighten because the coupling may be damaged.

5. Connect the angled end of the water hoses (C) to the filling valve at the bottom of the rear frame. Turn the coupling manually until it is tight.

6. Using pliers, tighten the coupling an additional two-thirds turn. Do not overtighten because the coupling may be damaged.

7. If you detached the cold water hose from your washer, attach the hose to the free end of the Y-connector, tighten the coupling by hand until it is tight, and then, using a pliers, tighten an additional two-thirds turn.

8. Open the cold water tap, and then check for any leaks.

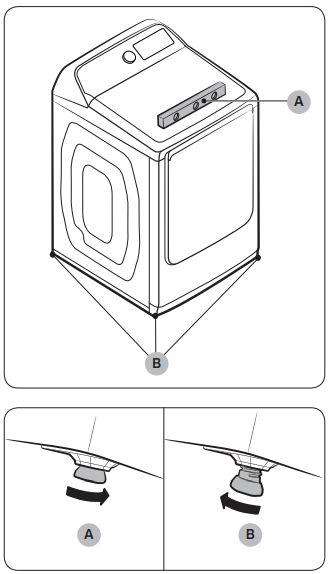

To ensure optimal performance, the dryer must be level.

Using a level (A), check if the dryer is level side to side and then front to back. If the dryer is not level, turn the leveling feet (B) clockwise to lower the dryer or counterclockwise to raise the dryer.

NOTE

• To set the dryer to the same height as your washer, fully retract (A) the leveling feet by turning them counterclockwise, then loosen (B) the feet by turning them clockwise. Once the dryer is the same height as the washer, follow the directions above to level the dryer.

• Adjust the leveling feet only as much as necessary to level the dryer. Extending the leveling feet more than necessary can cause the dryer to vibrate.

Make sure all gas connections, the exhaust line, and all wiring is connected correctly. Then, plug the power cord into a power source and check the dryer’s installation and operation using the final checklist in Step 7 below.

When installation is complete, confirm that:

CAUTION

The burner may not ignite initially due to air in the gas line. Allowing your dryer to operate on a heat setting will purge the line. If the gas does not ignite within 5 minutes, turn your dryer off and wait 5 minutes. Be sure the gas supply to your dryer has been turned on. To confirm gas ignition, check the exhaust for heat.

After the dryer is installed, start the Vent Blockage Test to check if the duct system is properly installed. The Vent Blockage Test automatically detects the status of the ducts and reports any blockage or problems. Proper ducting can reduce drying time and save energy.

NOTE

The Vent Blockage Test must run when the dryer is cool. If the dryer warms up after the installation check, run the AIR FLUFF cycle for several minutes to reduce its internal temperature.

- To stop or cancel the Vent Blockage Test, press the Power button to turn off your dryer.

- During the test, if “dc” appears in the display, make sure the door is closed. If “C1” is displayed, see if there is laundry inside drum. If there is, stop the test and remove it. Then, start the test again.

- The results remain on the display for about 5 minutes and then automatically turn off. You can turn the results off immediately by pressing the Power button.

NOTE

Cleaning

Clean all old ducts before installing the dryer, and make sure the vent flap opens and closes freely. We recommend that you to clean the exhaust system annually or on a regular basis.

WARNING

To reverse the direction of the door, we recommend that you contact a qualified technician.

1. Put a soft rug on the floor to rest the door on after you have removed it. This will prevent the door from being scratched.

2. Unplug the power cord of the dryer.

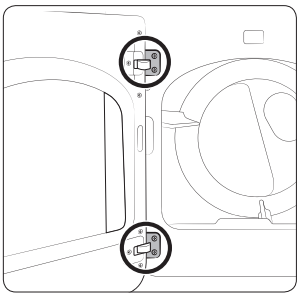

3. Remove the four hinge screws from the door, and then remove the door by lifting it up slightly.

4. Remove the two screws from the lever holder, and then remove the holder cover.

5. Put the lever holder on the other side as shown, and then tighten the screws. Install the holder cover on the opposite side as shown.

6. Use a flat-head screwdriver to remove the two hinge covers from the original side. Install the hinge covers on the opposite side as shown.

7. Locate and remove the 10 screws as shown. Note that screw B (x2) is longer than the others.

8. Remove the glass holder, and switch the positions of:

a. the hinge cover and the door handle.

b. the hinge holder and the glass-guide holder

9. Remove the door lever, and then move it to the other side as shown.

10.Remove the hole cover (C), and then insert and tighten the glass holder using the removed 10 screws.

11.Install the hole cover on the opposite side as shown.

Here are a few things you should know before starting your dryer.

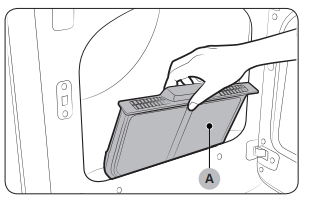

Lint filter

To prevent a risk of fire, make sure to clean the lint filter before or after every load

1. Turn off the dryer.

2. Open the door and pull out the lint filter (A) from inside the drum.

3. Remove the lint, and then clean the lint filter.

4. Reinsert the lint filter, and then close the door.

CAUTION

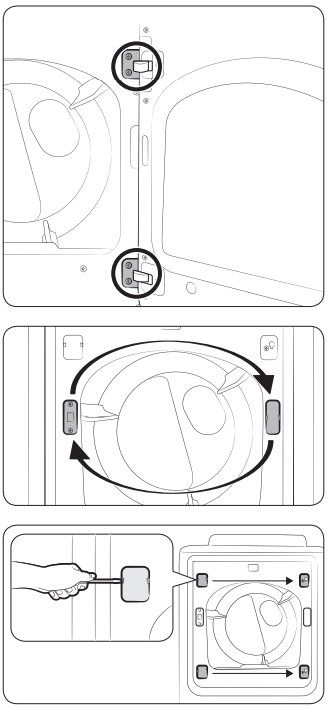

Some models come with a drying rack which is inserted into the drum at the factory. If your model came with a drying rack, remove the rack from the drum before you use the dryer for the first time. To remove the rack, pull the rack straight up, and then take it out of the drum. Remove the drying rack from its packaging and store the rack for later use.

If a drying rack is not provided, you can purchase it at a local Samsung service center. (Part Code : DC61-03052B) To use the drying rack, follow these steps:

1. Insert the drying rack (A) inside the tumbler with the filter handle to the front.

2. Insert the rear legs of the drying rack into the recessed areas of the rear wall, and then press down the middle of the drying rack to secure it in place.

3. Put items to dry on the rack. Make sure to leave space between the items for air flow.

4. Press Rack Dry, and then select the drying time.

5. When the items are dry, remove the them from the dryer, and then remove the drying rack.

WARNING

WARNING

To reduce the risk of fire, electric shock, or injury to persons, read the “Safety information” before operating this appliance.

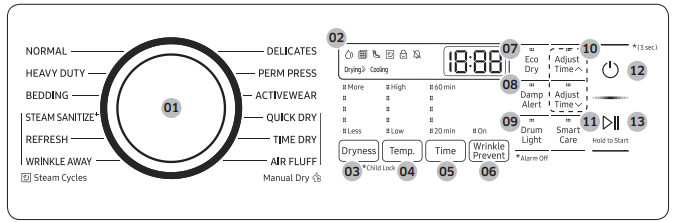

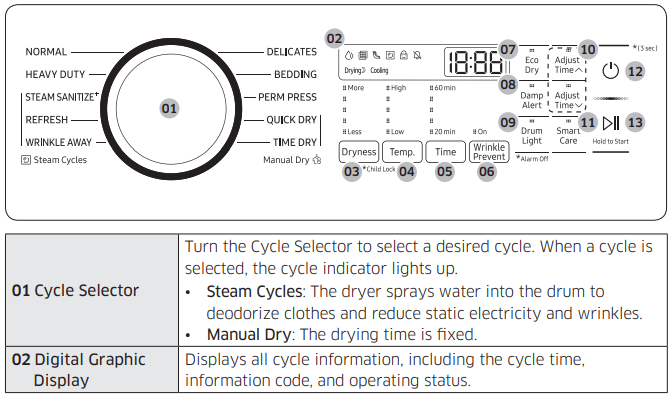

DVE(G)54R7600*

DVE(G)54R7200*

NOTE

Do not take extremely tangled items from your washer and put them into the dryer. They can degrade the drying efficiency of the dryer or cause the door to open. We recommend that you untangle the items before putting them into the dryer. Also, do not put objects on the dryer, especially on the control panel.

CAUTION

Do not spray water directly onto the control panel. This may cause a system failure.

To change the cycle during operation

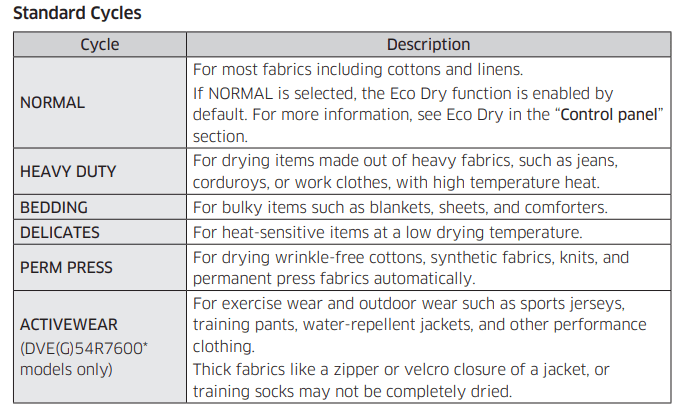

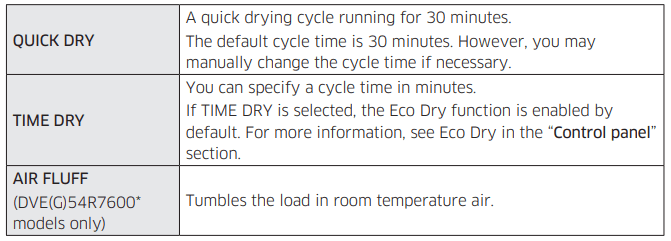

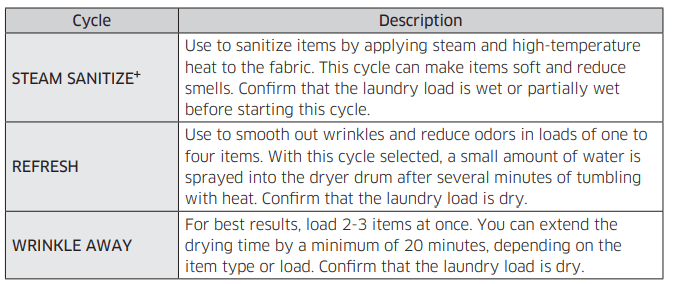

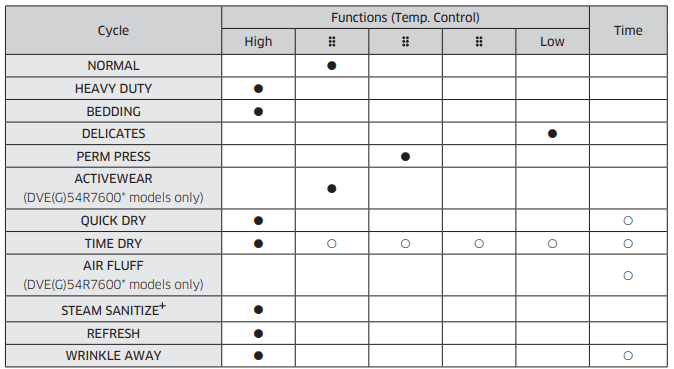

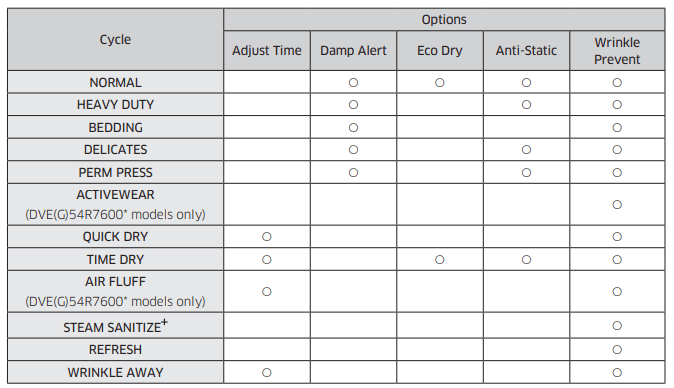

Standard Cycles

Manual Dry

You can change the drying settings manually to your preference.

Steam Cycles

Use steam to reduce wrinkling and odors on items.

NOTE For best results, follow the load size recommendations for each dry cycle.

Large load: Fill the drum to about 3/4 full. Do not add items over this level as they need to tumble freely.

Large load: Fill the drum to about 3/4 full. Do not add items over this level as they need to tumble freely. Medium load : Fill the drum to about 1/2 full.

Medium load : Fill the drum to about 1/2 full. Small load : Fill the drum with 3-5 items, not more than 1/4 full.

Small load : Fill the drum with 3-5 items, not more than 1/4 full.

NOTE :  factory setting, :

factory setting, :  can be selected

can be selected

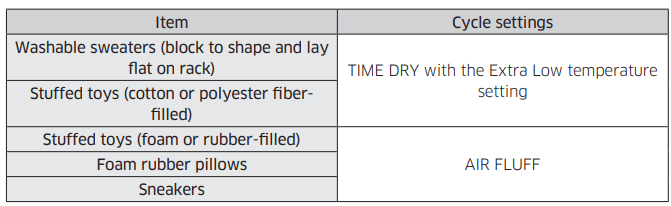

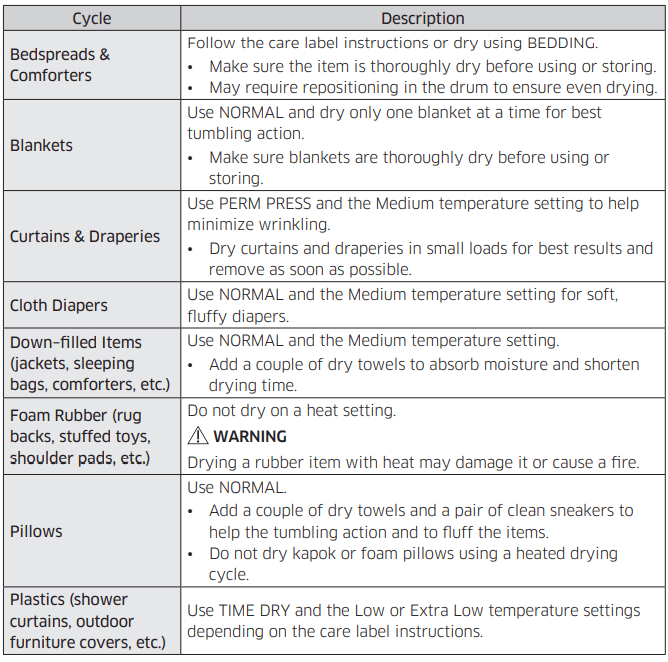

The best way to dry items is to follow the instructions on the care label. If no drying instructions are provided, see the following table for reference

WARNING

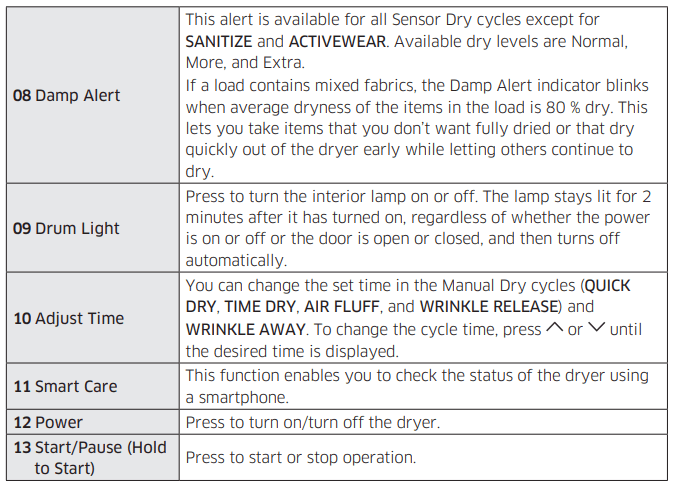

Child Lock

Child Lock prevents children from playing with the dryer. When Child Lock is activated, all buttons except for the Power button are disabled. To activate/deactivate Child Lock, simultaneously press and hold Dryness and Temp. for 3 seconds.

NOTE

Once Child Lock is activated, it will remain active even after you restart the dryer. If other buttons, except for the Power button, do not respond, check the Child Lock indicator. If the indicator is on, follow the instructions above to turn Child Lock off.

Alarm Off

You can turn the alarm on or off. When the alarm is off, the melody of cycle completion and the power-off beep will not sound. However, the other sounds stay active.

Smart Care

To enable this function, you must first download the SmartThings app at the Play Store or the App Store and install it on a mobile device featuring a camera function. The Smart Care function has been optimized for Galaxy & iPhone series (applicable models only).

NOTE

Keep the dryer clean for best performance and to lengthen its life cycle.

WARNING Certain internal parts are intentionally not grounded and may present a risk of electric shock only during servicing. Service Personnel - Do not contact the following parts while the appliance is energized: Control board and inlet valve.

Control panel

Drum

Powder coated drum

To clean the powder coated drum, use a damp cloth with a mild, non-abrasive cleaner suitable for easily marred surfaces. Remove cleaner residue and dry with a clean cloth. Dryer exterior

Exhaust system

If the dryer operates abnormally, first check the list of problems in the table below and try the suggested actions.

• Make sure the door is latched shut.

• Make sure the power cord is plugged into a live electrical outlet.

• Check your home’s circuit breakers or fuses.

• Press or tap Start/Pause (Hold to Start) again if the door is opened during a cycle.

• Clean the lint filter.

• Check your home’s circuit breakers or fuses.

• Some cycles do not require heating. Check the selected cycle again.

• For a gas dryer, make sure the gas supply is on.

• Clean the lint filter and exhaust duct.

• The dryer may have moved into the cool-down phase of the cycle.

• Turn off the Eco Dry option for the NORMAL or TIME DRY cycles. When the Eco Dry option is on, the dryer performs an air dry process in the beginning of the cycle to reduce energy consumption. The air dry process does not use heated air, so you may feel that the dryer is not being heated, but this is normal.

• Check all of the above, plus.

• Make sure the exhaust hood outside your home can open and close freely.

• Check the exhaust system for lint buildup. Ducting should be inspected and cleaned annually.

• Use a 4” rigid metal exhaust duct.

• Do not overload. 1 wash load = 1 dryer load.

• Dry heavy items and light weight items separately.

• Large, bulky items, such as blankets or comforters, may require repositioning to ensure even drying.

• Make sure that your washer is draining properly and extracting adequate water from the load.

• The load may be too small to tumble properly. Add a few towels and restart the dryer.

• The load may be too large to tumble properly. Remove some items and restart the dryer.

• Clean the lint filter.

• Check the load for objects such as coins, loose buttons, nails, etc. Remove promptly.

• It is normal to hear the dryer gas valve or heating element cycle on and off during the drying cycle.

• Make sure the dryer is leveled properly as outlined in the installation instructions.

• It is normal for the dryer to hum due to the high velocity of air moving through the dryer drum, fan, or exhaust system.

• Seams, pockets, and other similarly heavy areas may not be completely dry when the rest of the load has reached the selected dryness level. This is normal. You can choose a higher dryness level or a cycle that involves a higher dryness level.

• If one heavy item is dried with a light weight load, such as one towel with sheets, it is possible that the heavy item will not be completely dry when the rest of the load has reached the selected dryness level.

• For the best drying results, dry heavy items and light weight items separately.

• Household odors from paint, varnish, strong cleaners, etc. may enter the dryer with the surrounding room air. This is normal as the dryer draws the air from the room, heats it, pulls it through the tumbler, and exhausts it outside.

• When these odors linger in the air, completely ventilate the room before using the dryer.

• Use a cycle featuring the Refresh function. If odors persist, wash and dry the item again.

• Use the REFRESH cycle. If odors persist, wash and dry the items again.

Lint on clothes.

• Make sure the lint filter is cleaned before every load. For clothes that naturally build up lint, clean the filter during the cycle.

• Some fabrics are lint producers (for example, a fuzzy white cotton towel) and they must be dried separately from clothes that are lint trappers (for example, a pair of black linen pants).

• Divide larger loads into smaller loads for drying.

• Check pockets thoroughly before drying, then dry clothes.

• Remove lint inside the drum before drying.

Items still wrinkled after WRINKLE PREVENT (WRINKLECARE, WRINKLE RELEASE).

• Small loads of 1 to 4 items work best.

• Load fewer items. Load similar-type items.

• Take out the items immediately after drying is complete.

Water drips from the nozzle when STEAM CARE starts.

• This is steam condensation. The dripping water will stop after a short time.

Sprayed water is not visible during STEAM CARE.

• Sprayed water is difficult to see when the door is closed.

• Sensor Dry automatically senses the moisture in the load and shuts the dryer off when the selected dryness level is reached. The drying time can change according to the type and amount of laundry. See the cycle chart for reference.

If a problem persists, contact a local Samsung service center.

If the dryer fails to operate, you may see an information code on the display panel. To determine what you should do, check the list of codes in the table below, and then try the suggested actions.

Operating the dryer with the door open.

• Make sure the door is properly closed.

• Make sure laundry is not caught in the door.

Invalid power source frequency.

• Try restarting the cycle.

• If this information code remains, contact a Samsung service center.

Electronic control problem (Invalid Communication).

• Contact a Samsung service center.

High temperature heating check

• Clean the lint filter.

• If this information code remains, contact a Samsung service center. (enter the line test mode)

The electronic control needs to be checked.

• Check if power is supplied properly.

• If the information code remains, contact a Samsung service center.

The Thermistor1 resistance is very low or high.

• Check for a clogged lint screen

• Check if the vent system is restricted.

• If this information code remains, contact a Samsung service center.

The Thermistor2 resistance is very low or high.

• Check for a clogged lint screen.

• Check if the vent system is restricted.

• If this information code remains, contact a Samsung service center.

Incorrect door switch.

• Contact a Samsung service center.

If any information code keeps appearing on the display, contact a Samsung service center.

Samsung DVE54R7200W/A3 | File type: PDF | Filename: Samsung DVE54R7200V:A3, DVE54R7200W:A3 7.4 cu. ft. Electric Dryer with Steam Sanitize+ in Black Stainless Steel.pdf | Size: 15.35 MB | Language: English, Spanish